TL/DR: I asked ChatGPT to design a chair based on a pile of scrap wood, and then I built the chair.

A while ago I wrote about how I wanted an AI for carpentry. Specifically, I didn’t want something which replaced me, or the interesting bits of work, but something more like a smart carpenter’s mate, to do some of the sums and make interesting suggestions, and leave me to do the fiddling and the sanding. A collaborator, not a god.

Here is the wood that was knocking around on my balcony, left over from a few things:

And here is the prompt I gave OpenAI’s ChatGPT 4:

I have a pile of scrap wood and I would like to make a chair. I have a saw, a drill, screws, and wood glue.

Please give me step by step instructions for making a chair from the following materials, using as little wood as possible.

4 pine panels:

- 18, 180, 490 mm

- 18, 255, 490 mm

- 18, 255, 490 mm

- 18, 255, 490 mm

1 plywood sheet:

- 4, 480, 850 mm

1 L-shaped laminated chipboard sheet:

- 15, 280, 410 mm missing 130, 135 mm cutout

1 20mm diameter dowel, 1900 mm long

1 pine or fir plank

- 20, 95, 1300 mm

5 wood beams

- 50, 50, 890 mm

- 50, 50, 900 mm

- 50, 50, 980 mm

- 50, 50, 980 mm

- 50, 50, 1030 mm

There was a bit more to it than that: I had some issues formatting the prompt in a way that didn’t crash the chat client, and we also went back and forth on a backrest. I also tried to push for a more interesting design, in the way I described in the original post, but this resulted in something I could not make (materially and physically) – and wasn’t very interesting either. You can read the whole transcript here.

So, this is what we settled on:

Materials Needed:

- Plywood Sheet: For the seat.

- Pine Panels: For the backrest.

- Wood Beams: For legs and support structure.

- Dowel: For additional bracing.

- Tools: Saw, drill, screws, and wood glue.

Cutting Plan:

- Seat: Use the plywood sheet to cut a rectangular seat, 480 mm x 400 mm.

- Backrest: Select one pine panel (255 mm x 490 mm) and trim if necessary to match the width of the seat for aesthetic continuity.

- Legs/Support Structure:

- Front Legs: Cut two pieces from the beams to the desired seat height (about 450 mm).

- Rear Legs/Backrest Support: Use the longer beams (980 mm or 1030 mm) and cut them so they can serve both as rear legs and extend upward to support the backrest. The total length should support a standard seat height plus the backrest height, roughly 900-1000 mm depending on your desired backrest angle and height.

- Seat Supports: Use leftover wood or the pine/fir plank to create support planks that run underneath the seat for added stability. Cut these to match the width of the seat (400 mm).

Assembly:

- Prepare the Seat: Attach the support planks to the underside of the plywood seat using wood glue and screws for extra stability. Space them evenly to distribute weight.

- Attach Legs:

- Front Legs: Secure the front legs directly to the underside of the seat at its corners with screws and wood glue.

- Rear Legs/Backrest Support: Align the rear legs so they support the seat and extend up to support the backrest. Attach them to the underside of the seat and the lower end of the backrest.

- Install the Backrest: Attach the backrest to the extended rear legs using screws and glue. Ensure it’s firmly in place and offers comfortable support.

- Bracing with Dowel: For additional lateral stability, use the dowel to create cross-braces between the legs. Cut the dowel into pieces that fit between the legs under the seat and halfway up the rear legs/backrest supports.

Finishing Touches:

- Sand the chair thoroughly to smooth out any rough edges and corners.

- Apply a finish of your choice to protect the wood and enhance its appearance.

This approach makes efficient use of your materials while providing a sturdy, comfortable seat with a backrest. The extended rear legs contribute to a streamlined, elegant design, and the under-seat supports ensure durability and weight distribution.

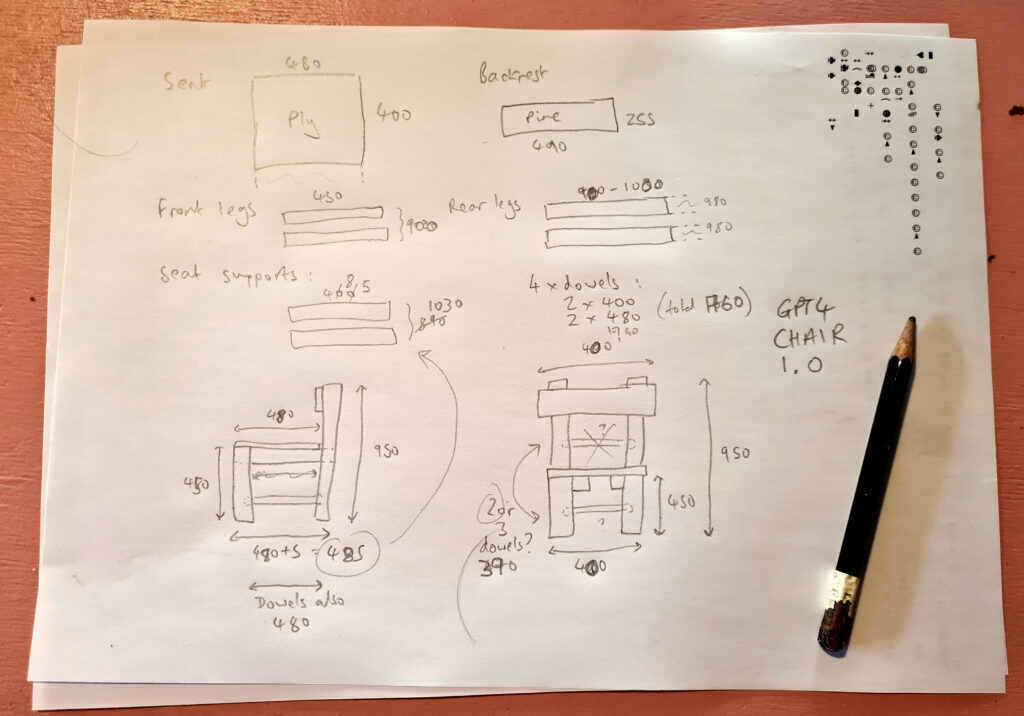

Based on this description, I worked up a rough plan that made sense. I tried to be as literal as possible. I suspected that the dowel braces between the legs would be necessary, and they very much were:

The chair did not take very long to build – even on a narrow balcony, in the dark – and I didn’t try too hard to make it nice. My saw is not very good; I sanded things down a bit; I glued where necessary. I tried to interpret the instructions as literally as possible. I decided where the screws and glue should go (twelve screws). You can sit in the chair.

My first impression of the chair was that this is what you get when you ask someone who has read a lot about chairs, but has never sat in one, to design a chair, which is exactly what it is. To be fair, it did a pretty good job.

My main concern building it was that the plywood seat was much too thin. It still feels very thin when you sit in it: it creaks and gives. But it holds – so far – and it’s perhaps more comfortable than a thicker, more rigid seat would have been.

It is what I wanted in that regard: minimalist – in the sense of using the absolute minimum of material – and it pushes at the boundaries of what I would have done myself.

My go-to example of what I mean here is the Optometrist Algorithm, which I wrote about in New Dark Age. The Optometrist Algorithm was designed, by Google, to improve nuclear fusion experiments. It’s an algorithm which works alongside human researchers, as a collaborator, serving to push their exploration of a problem space just a little bit further, or in novel directions, than they would do alone.

I would not have designed this seat: I would have used another piece of thicker wood. And this would probably have been less efficient. This is all the wood I had left at the end (from the pieces which ChatGPT selected):

The one change I would make would be to cut that remaining bit of ply down and use it to laminate the seat, doubling its thickness. Maybe.

The chair also felt too big. Here’s a size comparison with an IKEA folding chair:

That’s still not terribly clear, but it’s much taller, and deeper, than most chairs I have (I doubted the dimensions so much I clarified, in the chat, which way round the seat should be). But, again, I’m not sure I disagree. I’m 6’0, and it feels the right size – it makes me feel like a lot of chairs are too small for me. Plus, again: efficiency. It used all the wood. It does look very big though. It looks a bit weird. A slightly uncanny chair.

I’m not including here the images that ChatGPT made to accompany the instructions; you can see them in the transcript, but they’re not very helpful, and don’t match the descriptions in a useful, technical way. They are still the same sort of thing though: generic images of chairs, rather than generic descriptions of chairs.

I’m still a bit disappointed that other prompts which asked the programme to go a bit crazier with its design didn’t pan out. Perhaps a chair isn’t the best thing for playing with here: humanity has converged on pretty much the best minimal chair design possible without AI’s help, it’s hard to improve on that. But it’s nice that after years of trying to peer inside the machine, I get to explore in more practical ways what comes out of it.

It should be noted that this chair is built on the stolen labour of everyone who’s ever put something on the internet (including many who passed centuries before the internet was invented). The energy use is not good. I didn’t make this with ChatGPT: I made it with a partial history of all previous chairs, and I held myself back from making it “better”. But it’s something to think with.

I learned to make chairs from Enzo Mari, Donald Judd, my grandpa, YouTube. What the machine is good at is numbers, efficiency, tolerances (maybe). What can we do with that which is more interesting than putting people out of work? Which is more, genuinely, generative? Which is more interesting than more computers? Which, ultimately, builds agency rather than contributing to our general disempowerment us? That, at least, is what I mean by collaboration. We learn together.

Edit 19/3/24: As a couple of people have pointed out, this feels like the opposite of generative AI. The machine can only use the tools and materials I have to hand: it’s restrictive, yet paradoxically more productive as a result. Something to think about.

Comments are closed. Feel free to email if you have something to say, or leave a trackback from your own site.